wire edm machine is an electro process

The nature of the Wire EDM process means that you can achieve shapes and structures that are next to impossible with other CNC methods and can give you incredible results. Wire EDM Wire Electro Discharge Machining or WEDM involves a continuously spooling conductive wire the most widely used is brass.

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Usually the work piece and wire are submerged in deionized water.

. Wire EDM is a type of CNC machining technology capable of unique results. You are unaware of many items that are made out of electrical discharge machining. The theory on which Electrical Discharge Machining EDM is based is centuries old.

An electric discharge between the wire and the conductive material produces some sparks which are precisely guided to cut through the material to achieve the desired cuts. Wire EDM uses a straight tensioned wire as the electrode which is slowly drawn through the workpiece to cut a ribbon-like path. Both the workpiece and the wire are submerged in the dielectric fluid.

What is Wire EDM. It offers the finest kerf process available for cutting metals. An EDM drill uses a tubular electrode to burn a hole through conductive material.

The discharge causes the melting and probably the vaporisation of a minute piece of material slowly eating. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece. If you change to 015mm or 01mm electrode wire you must reduce this tension value otherwise it will be in the process of.

Your machine has the arrangement to provide fresh wire continuously for effective cutting and the path of the wire is controlled and guided by the. Wire electrical discharge machining also known as wire EDM is a contact-free machining method that uses a thin metal wire to conduct an electrical current. The process often used in manufacturing components and tools is similar to cogging and grinding.

The process is applicable only for electrical conductive materials such as metals. Its quite like a cheese cutter. The starts with the thin piece of electrically charged wire made of brass of any other material being held in position by the upper and lower guide.

Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method. Your Wire EDM machine uses a thin electrically conductive wire generally brass as an electrode to cut the workpiece to create the desired profile or shape. In the 1980s after the continuous development in machining capabilities the.

Wire Electrical Discharge Machining Wire EDM is a plasma machining process that uses an electrical discharge between a wire and a conductive workpiece. Wire filters and other consumables used on wire EDM machines. A metallic wire usually brass or copper has high voltage electrical discharges passed through it that allows it to cut through the entire thickness of the material.

Wire electrical discharge machining WEDM also known as wire-EDM is an improved modification of EDM. It can be plastic metals for any material that may result in a. Electrical Discharge Machining or EDM is a manufacturing operation used for shaping different workpieces into complex parts.

A power supply generates rapid electric pulses that create a discharge between the workpiece and electrode the wire. A specially designed tool emits sparks in terms of thousands cut the material. Only a slight bit wider than the wire electrode itself.

How the Wire EDM Process Works. This method remove materials by using a controlled and fast frequent electrical charges. The cut width kerf is very narrow.

The wire tension in the machine configuration is incorrectThe system defaults to set the edge-finding tension to 12. Wire EDM which came into commercial use in the 1960s uses a wire stretched taut as the electrode. A Swiss firm Agie in 1969 established and supplied the worlds first WEDM machine.

These machines had prolonged manufacturing rate with a material cutting ability of 21 mm 2 min. Cutting will either take place from the edge or a hole will be. The current creates sparks which are used to accurately cut a workpiece into the pre-programmed design.

Line Diagram Of Wire Cut Edm Process Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

What Is Wire Edm Electrical Discharge Machining Xact

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube

Schematic Diagram Of A Wire Edm Machine Download Scientific Diagram

Wire Cut Edm Process 2 Download Scientific Diagram

What Is Wire Edm Electrical Discharge Machining Xact

Study Of Process Parameter Of Wire Electric Discharge Machining The Review Semantic Scholar

Wire Edm Find Suppliers Processes Material

Schematic Diagram Of Ezeecutplus Wire Edm Download Scientific Diagram

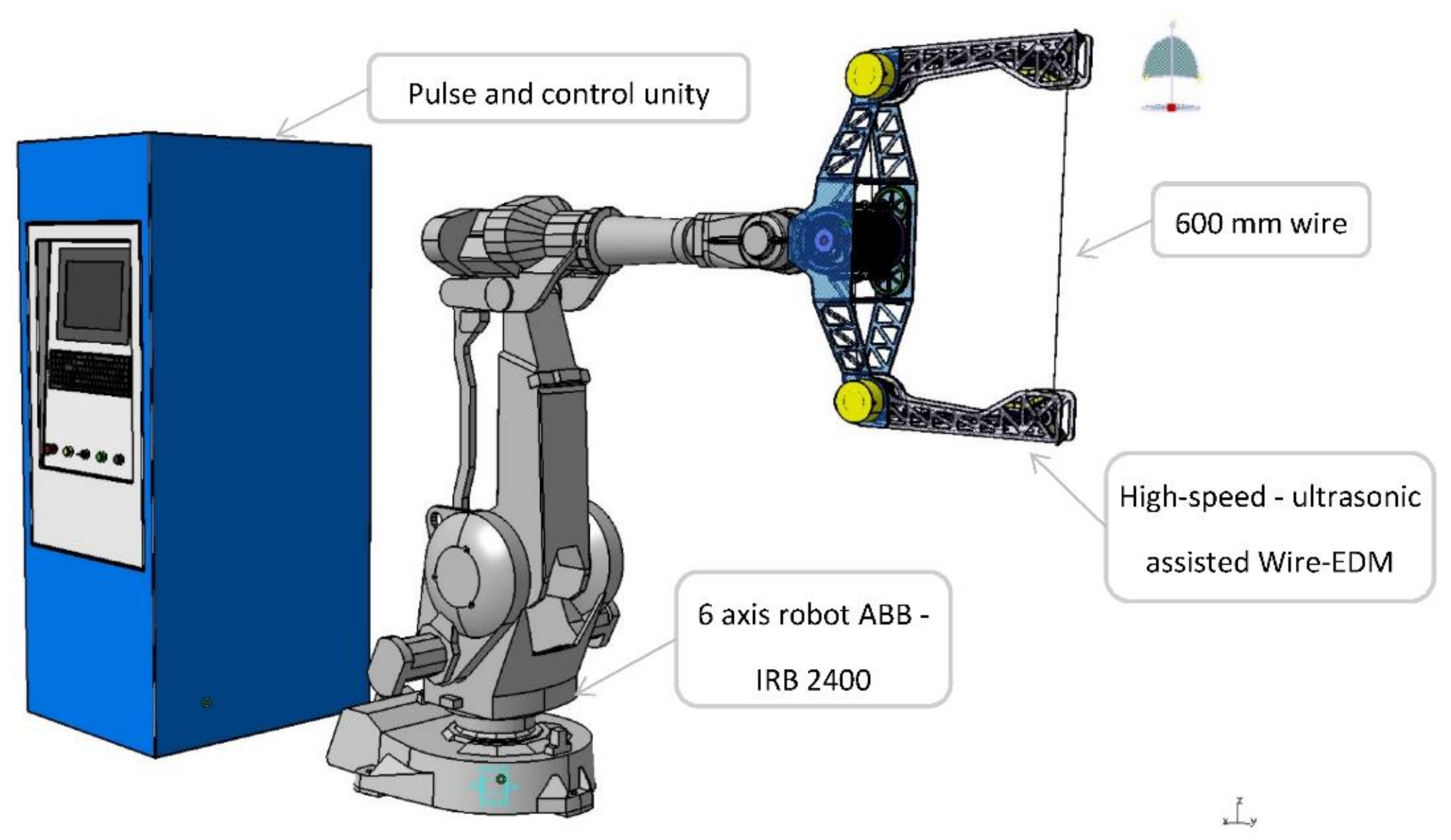

Machines Free Full Text Conceptual Design Of A High Speed Wire Edm Robotic End Effector Based On A Systematic Review Followed By Triz Html

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Wire Electric Discharge Machining Wire Edm Youtube

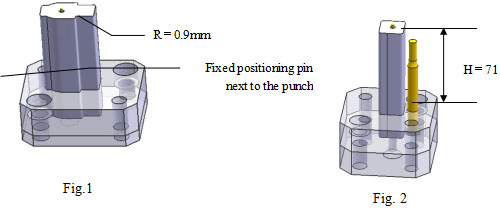

Processing Technology Of Punch And Die With Cnc Wire Cutting Edm Beijing Dimon Cnc Technology Co Ltd

Wire Edm Introduction As We Build Our Knowledge Database We By Factorem Medium

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Wire Machining Hotsell 53 Off Www Ingeniovirtual Com

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking